Insight TGE

Insight TGE

Technical Lead Process Safety

Interview with Dr. Karina Almeida Leñero

Liquid Gas Terminals – Designed with Safety at Heart” was the topic of your presentation at last year’s Hazards30 conference. Can you tell us a little bit more about that in the context of your role at TGE?

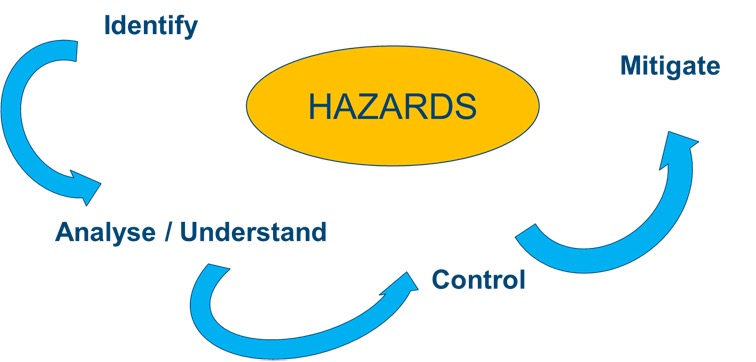

Safety is of paramount importance for the design, construction and operation of any industrial installation handling large amounts of flammable fluids. The role of the Process Safety Engineer is to ensure that all potential hazards arising from a new terminal or the modifications to an existing one are identified early in the lifecycle of a project, that the consequences and risks are properly understood and mitigated to a level that we call “tolerable”. That means that the risk that people are exposed to as a result of the terminal operations are much lower than the everyday risks people take like traffic accidents, falling from a height or even infectious diseases.

Process safety engineers always assume that something will go wrong, despite the best process design and equipment and material selection. We ask a lot of “what if” questions: What if someone drops a heavy tool over a pipe and breaks it? What if there is a big leak that then catches fires? We look in detail at all those scenarios to understand what is the worse that could happen. For this we use a number of techniques, including brainstorming workshops and mathematical models. We then find ways to “mitigate” these scenarios. That means to ensure that even in case of an accident, we minimise the harm to people the environment and the plant and equipment, in that order.

For me, the most important part of Process Safety are not the calculations or models, but it is making sure that the people in and around the facilities TGE designs and builds go home safely every day. That both excites me every morning and keeps me awake at night!

What is the difference between a “Technical Lead” and a “Team Leader” and what is the teamwork like in the Process & Safety department?

As Technical Lead, I make sure that my team has the required technical competences and skills to deliver the Process Safety scope of a project. I look at whether people require training, either external, internal or training on the job. One of my favourite parts of the job is training colleagues who have little experience with Process Safety and helping them understand why it is so central to the success of a project. I also provide guidance and mentoring to team members and try to balance the team’s tasks so that everyone has work that is interesting to do and where they can learn something.

Another part of my role is to ensure the team has the right tools to do the work, be it software, or access to the right standards and books, or knowledge of industry best practices. I also keep abreast of the latest developments in Process Safety and share them with the team.

Finally, I take care of the interfaces with other departments because Process safety is by definition a multi-disciplinary job. We work together with process, instrumentation, electrical, civil and structural engineers, as well as our construction colleagues on site. This is what I highlighted in the Hazards paper you mentioned above.

I guess the biggest difference between a Technical lead and a Team Lead is that I do not have disciplinary responsibility for my people.

Teamwork in our department is great, people are really open to work with each other and to learn from each other. The most senior engineers are very willing to coach the younger ones, but also to challenge them to help them develop. Most of us have very good personal relationships with our colleagues, even if the team is part in Bonn, part in Manchester, UK. We were used to virtual working even before COVID forced us all to do it.